|

A JOURNEY TO CREATIVITY

BY STEVE BOSQUETTE steve@portlandinsurance.com

| Creativity is a wonderful thing. Where does

it come from? Why do some have it in abundance, and how can we get more? These are all

rhetorical questions of course. Some of the happiest days of my life have been when I

could be creative in some form or another. Most recently it has been by designing and

building a boat, but not just any boat; a SCHOONER! |

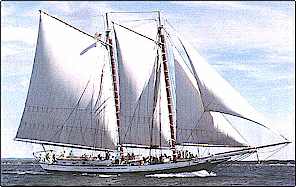

The Schooner Grace Bailey

|

| This recent event began last spring when I was feeling my

Catalina 22 "Sea Rose" was getting smaller, you know that affliction

"Biggerboatitis". My wife and I do weekend cruising here along the Maine coast,

mostly in Casco Bay. The boat is a good sailor but is limited in accommodations. We do

manage to go on a week long cruise each year to Penobscot Bay some 50 or so miles up the

coast. I was thinking of selling it and buying a larger boat. I started looking on the net

for boats for sale and stumbled into John Khonen’s site, "The Mother of all maritime

links page". You can get lost in that site for days! About that same time the

reality of college expenses, for my daughter Susan, hit home dramatically and we decided

to postpone the sale of the boat. |

Folding Schooner

|

This left the juices flowing still and I became

hooked on the net! I started spending a lot of time finding and perusing boat plan sites.

I was looking for schooners to build. Although the ones I found did not solve the bigger

boat problem, I became obsessed. |

| Having been born and brought up on the

Maine coast I was smitten by the grandeur and grace of the schooner rig. But I discovered

very few designs for schooners. Phil Bolger has inspired me for years with his unique

designs and I almost built a "Folding Schooner" some years ago, but I never got

around to it. |

| The saga continues! I used a search engine to find

sites about Bolger designs. I struck pay dirt when I found "The Light Schooner" site.

What a nice boat. I read everything I could find. After many hours and much consideration

I decided that it was too narrow and carried too much sail for my wife’s

sensibilities. So I traveled on. |

The Light Schooner

|

| I found the book "BOATS WITH AN

OPEN MIND" by Phil Bolger and bought it. I found two schooners in it; "THE

SINGLEHANDED SCHOONER" and |

The Singlehanded Schooner |

"THE SCOW SCHOONER". The first boat was

too small, very narrow and shorter than my Catalina. I faxed Phil to see about the

availability of plans for the scow but he said the design never went beyond the concept

stage. So here I was, left with building the "LIGHT SCHOONER" or the

"FOLDING SCHOONER" neither of which met my needs exactly. |

| The next step was to find a design that

I could adapt a schooner rig to. I found a wonderful site, Stevenson Projects. |

| Their site has a section called pocket cruisers.

The boat that interested me was the "Vacationer". It is designed after the

Friendship Sloops which originated here in Maine. It has captured the essence of the sloop

including the clipper bow. The construction technique is easy, so I bought the plans. I

E-mailed the designer, Mike Stevenson, about developing the schooner rig for it and he

thought that might be fun! While I was waiting for the plans to arrive I was having second

thoughts about using someone else’s design and modifying it. Then it hit me that

since I had designed and built a number of boats before that maybe I could develop a

design myself. So I did and time will tell how it successful it will be. |

Vacationer

|

THE DESIGN PROCESS

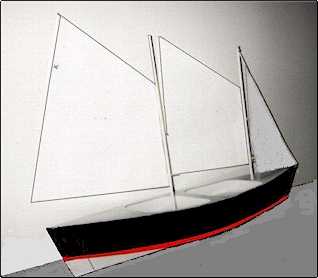

Model

|

In my web travels I came across a hull design

program by Gregg Carlson. It is

freeware so I downloaded it and began to design the hull of the schooner. It is 23 feet

long, 6 feet beam and double ended. I have always loved a double ended boat for the grace

at which it goes thru the water. I like the full keel on the Stevenson designs so

incorporated it in the program. The program calculates the center of buoyancy and the

center of lateral resistance. I also gives the area of the lateral resistance. |

| When it "looked right" I

sketched the schooner sail plan, located the center of effort of all sails and overlaid

the sail plan onto the line drawing of the hull, remembering to lead the center of effort

in relation to the center of lateral resistance. Theoretically the boat should sail well

balanced. The fun part of designing a prototype is to anticipate the launch and see if the

thing sails well. If not I’ll experiment with the configuration until it does. Since

my ultimate goal is to offer plans for sale for a line of homebuilder schooners, I became

more creative and made a web site for the idea. It is called Curtis Schooners and can be

found at https://www.portlandinsurance.com/cs

. It was great fun building the site and in the meantime getting to know our own Chuck

Leinweber who was of great assistance and encouragement. |

THE CONSTRUCTION PROCESS

|

With all that in place I was chomping at the bit to

start building. I used ¼ AC X fir plywood for the web sections and 1 ½ x ¾ spruce for

the web reinforcements. I cut the appropriate notches for the chine logs and sheer

stringers glued it all together with Dap weldwood plastic resin and fastened all the parts

together with countersunk #6 x ¾ zinc coated screws. |

| I designed the boat so that the hull sides were

flat in dimension that is two feet by 24 feet. I takes three sheets of ¼ inch Lauan

plywood to make the sides. I cut the sides and butt blocked them with 1x4 spruce, cut the

angles for the bow and stern. |

|

| I filled the screw holes and surface voids of the plywood with

Elmer’s Exterior Project Wood Filler, which I found to be excellent for it’s

hardness when cured and it’s easy sandability. |

|

Now came the time to assemble the pieces! I mounted

the midship frame on a 6x6 landscape tie and fastened the sides to it using plastic resin

glue and screws. I prepared the stem and the stern post, glued and fastened them to the

sides and all of a sudden I had a boat. The shape was pleasing and I liked it! It sure

piques your interest when a boat arrives at this stage! Next I put the bottom panels on. I

designed the boat with double ½ inch ACX fir plywood so that there would be additional

weight down low where it would help the stability. The benefit , other than additional

weight, of the double bottom is that butt blocks are not needed. I staggered the seams

being sure to mark the locations on the top layer so that extra screws could be installed

to secure the area around the seams for a permanent joining of the layers. |

| This brings us up to date on this "Voyage to

Creativity". Additional pictures of the project are on the Curtis Schooner site for

your enjoyment! I will have a follow-up article for

Duckworks Magazine which will describe other design ideas associated with this schooner

that hopefully will be entertaining reading. I’m sure having fun with this project!

You too can design and build a boat! Sure you can!!! |

|

|