Littler Breton Update Part 3

Part 1 - Part 2 - Part 3 - Part 4

Chuck:

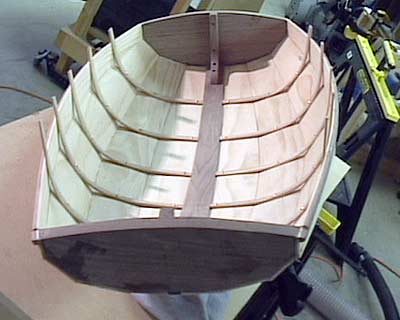

Here is the latest installment on the cradle pram.

Friday evening the sheer strakes were added. The only clamping

needed was at the ends and that was accomplished by one screw

to each end.

Saturday morning I took the picture with the Kari, mother to

be before I'd even trimmed the planks to length. She hides the

pregnancy rather well.

Saturday morning I made the rubrails. They are

walnut. 1/4" by 5/8" with a round over on the two

outer edges. I made a mistake and left one clamped to a sheer

strake while I went to buy some more lumber. Eveidently the

epoxy hadn't cured enough from the night before and it pulled

the plank away from the bow transom. The epoxy was all stringy

like what you'd see after stepping on chewing gum on a sidewalk.

The epoxy did manage to cure to a hard state after the plank

pulled away. That set me back a little on Saturday but by Sunday

morning I was back on track.

I just couldn't wait to see the inside of the

cradle so I unscrewed it from the strongback and took it outside

in the light for a little bit. the cradle is very light and

surprisingly stiff as it sits in the pictures.

Then I returned the cradle to the strongback to install the

rubrails and fill some screw holes.

A friend of mine graciously sent me some bronze holdfast nails

which I will use in the ends of the planks as kind of a belt

and suspenders thing.

The next Friday evening I milled the ash for

the ribs and bent a couple of them to see how they would go.

Rather than build a steambox, I thought I'd try just using hot

water in the kitchen sink. Since the longest ribs are less than

15 inches, I was able to fit them diagonally in the basin.

Hot water is kind of slow but it gave me time to get things

ready. For the test I only used the hottest water I could get

from the tap. I changed it once as it cooled. A stainless sink

isn't the greatest vessel for keeping hot water hot. After about

an hour I was able to bend the two forward most ribs into place.

Saturday I did the rest of the ribs. This time

I also boiled some water in the electric kettle although I don't

know if that really sped things up much. To keep the ribs submerged,

I used a kitchen pot filled with water. This worked quite well

and the worst part of the whole thing was the long trek from

shop to kitchen to shop with the intervening stairs.

I made my rove setting tool from a 1/2"

x 3" bolt by drilling a hole in it longer than the longest

rivets I have. It works quite well although I think riveting

would be less work if it had more mass. I was thinking of setting

it in a cylinder of lead and then wrapping the whole thing in

tape so I'm not handling the lead.

Riveting was something I was nervous about doing

but found its not that hard to do. I can see it would be easier

to do if you had a helper even on a little boat like this. It

was difficult to hold the boat still, keep the bucking iron

in place and mushroom the end of the rivet over the rove.

One thing I didn't anticipate with this design

is that the points of contact between the planks and ribs do

not occur at the seams as shown in all the books I have that

talk about riveting. Instead the contact points happen mid plank

so that's where the rivets are. Like the sheer thing, I don't

believe this would be good for a full sized boat but I think

it will work in in this cradle.

Dave Richards