Epoxy Ratio Scale - Variation on the Theme

by Tom Hamernik

I thought Joe's article was great.

I first tried the pumps, but found them messy (constantly dripping) and inaccurate since, without a doubt, one or the other would burp, making a mess and forcing me to re-measure. Changing the pumps to new bottles was messy, as well.

I resorted to maing tick marks on my mixing cups and pumping until I hit my marks. Ultimately, I had been wanting to convert over to measuring by weight, and a recent project need for epoxy plus Joe's article provided the impetus to make an epoxy balance.

I really like Joe's design, but I thought I would try something a little different, and even simpler to construct since I was in a hurry for that epoxy.

Although I used a couple of round headed screws for the pivot, it would be better to use something that comes to a point, such as a strip of wood having a triangular cross section, glued to the bottom of the scale.

My approach has both advantages and disadvantages when compared to Joe's.

One advantage that suits me is that by using separate cups for resin and hardener, you can pre-measure one or more batches well in advance of when you need the epoxy - useful for staging a big placement such as glassing the bottom of a boat. Also, when mixing, I often pour the mix back and forth between the resin and hardener cups to make sure the two components are thoroughly blended.

Another advantage is that you can mix pretty well any volume without having to hunt for the specific weight required to balance the Joe's scale.

Joe's scale is probably a bit quicker to use for a specific volume of mix, especially since you can quickly slide the cup against the stop and start pouring. And, since the distance from the pivot to the cup is flexible, the stop works with variable size cups. My version requires precise placement of the cups since the proportion relies on the distance from the cups to the pivot point.

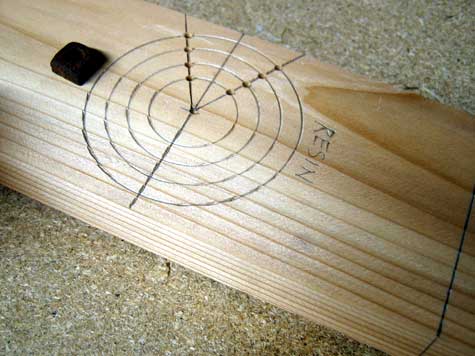

For the Raka epoxy I currently have, the mix ration is 100:43 (a little more than 2 parts resin to 1 part hardener by weight). So, the resin cup must be 43 parts from the pivot and the hardener must be 100 parts from the pivot. I drew concentric circles to help position the cups.

The diagonal lines with the holes are for pegs (although I haven't yet used them) that can be inserted to provide stops for whatever size cups are being used.

Very simple and quick to construct.

TJH