| I finally launched WÄASABI last

weekend, so I thought I would give you a summary of

the project from my perspective, and how I modified

Flyfisher

to accommodate a Piantedosi RowWing.

|

I retained most

of the design with the following changes:

(click images

to enlarge) |

I lowered the height

of the central compartment deck to just 5”

above the keel/hull, to permit the RowWing to

sit over the hatch. I installed an additional

sheet of ¼” ply, 14” wide and

the full length of the aft cockpit, to act as

a stringer to support the aft stanchions and hardware

for the RowWing.

|

|

| I added a pair

of 3” tall “half-frames” amidships,

just inboard of the bulkheads C & D, to add

strength to the gunnels and top strake amidships.

These added a lot of stiffness.

They also permit some shockcord to be used

as a drinkholder. |

|

| Under the

central compartment, I added 2 support knees

amidships, 1 fore and 1 aft just inside the

bulkheads, to dramatically increase the deck

strength, which I found too flimsy for my 190lbs.

I also screwed the cleats under the compartment

decking to the bulkheads, and for the forward

and aft compartments, I screwed cleats laterally

through the hull planks. This latter was critical

to again holding my weight without spreading

the hull. I also added additional ply to the

hatch covers themselves to support me.

|

|

In place of

threaded nuts, I built turning toggles for dogging

down the hatch covers. I felt they protruded

less, and were quicker to release and install

the hatch covers. |

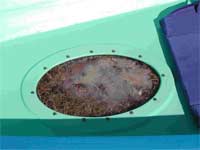

| I added a 10 x 15”

elliptical bottom window into the hull of the

forward cockpit. I took the installation design

concept from a page on the CLC website. I used

lexan polycarbonate, supposedly much stronger

than acrylic, and safer/lighter than glass. |

|

|

The design

concept included 2 parallel rub strakes alongside

the window on the bottom, just ½”

thick, to minimize scraping on the window when

on the hard. |

| I added

a Keel/skeg for the aft 5 ft. of the hull, 3/4”

wide x 5/8” deep. I’m not sure if

this helps tracking when I row or not, but it

certainly does not impede turning – she

still turns on a dime.

Instead of any half-round bronze for the stems,

I glued on an additional 1/4” strip to

the face of the bow stem, as a sacrificial bumper,

to be replaced if/when needed.

|

| I have drilled

some ¼” deep receiver holes in 3

places along the inwale in the forward cockpit. |

|

|

These will hold

the thin ash frames for a dodger I am building,

to act as a spray deck when I venture out in

rough weather.

|

| WÄASABI paddles

wonderfully with 1 or 2... |

|

|

... and also

rows very well. |

| I am delighted.

Now if she will catch fish! |

|

|

All the best,

Ben Stone

|

|