|

|

|

|

Hi Chuck, Thanks for publishing my last article, as promised I'm keeping you updated on the madness from down under.

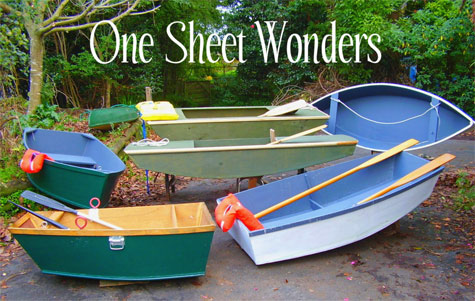

I have stated a yahoo group – One Sheet Wonders - All is going well we have about 47 members all obsessed with trying to make something fun and floatable out of one sheet of ply. Its more like a circus than anything to serious, we have some colorful characters in the group, no bearded women as yet.

Here’s what I’ve been working on during the winter here in New Zealand. I’ve built and designed 6 boats for this summer on a shoe string budget, they're inspired by Payson/Bolger type squareish flat bottomed craft. I’ve tested all 6 designs and they float me just fine at my 92 kg and 6ft 2 body dimensions. Depending on where you put your seating to transfer the weight evenly and remembering to keep low to the bottom they work as they should in protected sheltered waters really awesome like. All boats made from one sheet of ply, and a couple of bits of 12 inch pine. I’ve scribbled out plans for all 6 boats if anyone is interested in some serious delusion and fun.

Cheers

Phillip.

|

|

|

Scullmatix

Tried out the Scullmatix today at Lake Woodlands with my second generation oar and it's a treat. Can do 1.5 - 2.0 mph per GPS without any trouble. May be able to quicken things a bit with practice but it works well now. For me it seems to work best in a two handed mode, one hand on the oar over the skullmatix and the other hand on the extension shaft. The two handed mode makes it easy to maintain proper incidence....and now that I think about it, would make reverse easy.

Sculling one handed almost always ends up with the oar going wildly out of proper angle of attack after only a few strokes. May be an inherent problem with 12'-14' slightly limber oars. Second generation oar blade was carved out of a cedar plank and replaced one of the split tail oar blades.

Skip |

|

Keep up the good work

Hi

You may remember me from my little Chugger that I submitted to you some time ago

As always I absolutely enjoy Duckworks

The article titled "Another Approach to Shaping Foils" couldn’t have come at a better time – it is fantastic!

Keep up the good work

At present I am working on a 5m (16ft) microcruiser and will keep you posted as I go along

Regards

Manie

South Africa |

Thanks

Hello,

I just wanted to drop a note to you folks thanking you for your quick order processing and for carrying a great line of products that folks like me use in building our own boats. I only wish I had discovered your business sooner. I am telling friends who are currently working on projects to look at your products. I have placed several recent orders and everything was excellent.

I am attaching a pic of the boat I have build and am finishing up the sails on. The jib in the pic is made with all of the components I purchased from you.

Thanks.

Michael Daggett,

Portland, OR |

| Cedar Strip Canoe....yet another project....

Started on another project, I’ve been “bitten” by the “canoe building” bug pretty bad. Hopefully I’ll be ordering fiberglass soon, I don’t want to rush, I’ve been taking my time and enjoying working with wood.

The stripping is complete….the staples will be removed and the “faring” , “shaping” and sanding will begin…

Glynn Sirmans |

Cicada in 3K

Hi Chuck,

Here is Cicada in 3D. I have disassembled it and will reassemble with glue probably tomorrow night and get the bottom planked.

click the image above to enlarge

Tim

(Cicada is a 133% June Bug) |

| Pathfinder spotted in the Houston area

|

|

One Sheet dory

Hi Chuck,

I'm sure you're told this often,but your's is one of the boating sites I check every morning while taking a quick tea break at the office. Others include Gavin Atkin's intheboatshed.net, and these two sites between them have inspired me to try not just building boats, but designing also. I'm sure you're told this often,but your's is one of the boating sites I check every morning while taking a quick tea break at the office. Others include Gavin Atkin's intheboatshed.net, and these two sites between them have inspired me to try not just building boats, but designing also.

I originate from the UK, and spent most of my life in the East Midlands of England, 100 miles from the sea. In 2004 I moved with my family to New Zealand, and we now live with 200 metres of the Island Bay boat ramp on the Upper Waitemata Harbour, Auckland. Last year I thought it was about time I started to utilise that great recreational facility at my door step, and since then I've been crewing a racing yacht, dinghy sailing and I've built a kayak, a Selway-Fisher Dart II. I read many books from the library about boat building, from John Welsford's 'The Backyard Boatbuilder' to John Gardner's 'The Dory Book'.

And so I came to muse over whether it is possible to create a boat with recognisable dory lines, capable of floating a young person and possibly an adult of lighter build, from a single sheet of ply. So far I've only completed a 1:10 scale model of the design (well 3 models actually, and I now feel the lines are about right, but suspect the degree of rocker is a little too much). I've drawn the plans with dimensions in a CAD package and written instructions for stitch and tape building, which I have attached along with pictures of the model. I intend to build a life-sized version with my son, for his use on Island Bay, a shallow and sheltered stretch of the harbour, but will probably include more of a frame and use polyeurathane glue and stainless steel screws to avoid exposing him to epoxy (he's a messy worker). And so I came to muse over whether it is possible to create a boat with recognisable dory lines, capable of floating a young person and possibly an adult of lighter build, from a single sheet of ply. So far I've only completed a 1:10 scale model of the design (well 3 models actually, and I now feel the lines are about right, but suspect the degree of rocker is a little too much). I've drawn the plans with dimensions in a CAD package and written instructions for stitch and tape building, which I have attached along with pictures of the model. I intend to build a life-sized version with my son, for his use on Island Bay, a shallow and sheltered stretch of the harbour, but will probably include more of a frame and use polyeurathane glue and stainless steel screws to avoid exposing him to epoxy (he's a messy worker).

I don't know whether what I've included in this message provides anything publishable in a forthcoming reports page perhaps, but I'm keen to get other home builders to see the design and offer their opinion, and hopefully build an Island Bay Dory of their own.

Best regards,

Andy White

For more info about this design

or to let Andy know what you think, visit his blog:

https://analogbuilder.blogspot.com

|

|

Caprice

Hi Chuck,

The actual construction has officially started. I've attached a picture for you. I built all the bulkheads and side/bilge panels a month or so ago so today I just started putting it all together. Tomorrow I'll finish the bevels on the bulkheads and get it all on center and then epoxy the BH's to the side panels. Friday is calling for rain so I'll attach the bilge panels on Saturday and maybe even start on the bottom. I plan to completely finish the bottom (paint and all) before rolling her over.

I think storage won't be too much of a problem as I'm not doing the flood tanks. I'm going to use one section each port and starboard for drinking water and another section each port and starboard full of canned goods and heavy items. Once it's all in place if I find I'm still light I'll add some lead bricks inside the bilge to bring it up to design specs. Other than that I'm pretty much sticking to the plans. A couple of minor changes - I left the transom full except for just enough room for my outboard and the forward side panels on the bow which I brought from the cabin top to a gradual taper out to the bow (the same as the side panels in the cockpit)

I'll keep you updated on the construction. I'm keeping all my fingers crossed for a fast build; however I enjoy (love is probably more accurate) every bit of it so it doesn't really matter how long it takes. :)

Joe

____________________________

.... Here's an update... the hull is together and I will start glassing all the joints tomorrow.

I've attached a couple more pics as well. At this point it's upside down... did you flip yours over to do the inside seams? I'm just wondering if it will all hold together if I tried to flip it?

Take care,

Joe

____________________________

I imagine it's getting very warm in Texas now. It was pushing 100 degrees F here today. A bit warm for sanding and planing. :)

As you'll see from the pic attached, I am almost ready to start painting. Hopefully only another couple of week before she's done.

How was the Texas 200? I can't wait to get on the water. It's been 1 1/2 years since I sailed.

|

|

Take care,

Joe

|

|

POLLYWOG UNDER SAIL

Hi Chuck,

Well, I finally had a windy and challenging day at the lake with the sailing Pollywog. After waiting at the ramp for 30 minutes to get the boat into the water (a busy day at the lake), I was blessed with good winds, and gusts, that tested my boating skills. I quickly learned a lot about the boat, the sail, and my abilities, or lack thereof.

The first thing discovered was the best seating position, but only after trying them all. Being alone in the boat was an advantage because I could easily make changes without question, or confusion. With a good, constant wind, and sitting in the center seat, I discovered that the bow had a tendency to plow the water. Changing to the aft seat corrected the problem. After thinking about the cause, I concluded that as the boat heels to one side, the shape of the hull in the water changes, causing the center of buoyancy to move aft. Moving weight aft (in this case me) is a logical correction. All further sailing was conducted from this position, or on the floor in front of the aft seat, the only problem being that my body was at times in the way of the tiller. I have yet to figure how to simplify this situation, other than to raise the tiller over my head, shift my position, and place the tiller on the other side, which I did many times. With regard to sailing with a partner, I suspect if one person were to sit in the center and the other aft, balance should be met, as the finished design of Pollywog differs from my prototype by increased stern curvature.

The next test came as the winds shifted, ceased completely, or gusted momentarily. Adjusting the sail for these conditions proved to be fairly easy, just let out the sheet, or pull it in. The location of the sheet on the tiller proved to be just right, everything at the ready. Sailing into the wind required a lot of thought however, while sailing downwind was a breeze (no pun intended). Tacking from side to side, attempting to go upwind, was a challenge. The primary problem was to gain enough forward momentum to make a turn into the wind. Many times I was stalled in the process, and the sail just fluttered in the wind, the boat making no forward progress. Some boats do this better than others, and learning the technique for each boat takes time and patience. One good day of sailing is not going to resolve this, but I did determine that a gradual turn was easier to control, balancing the rudder with the sheet. My boating terms here may be lacking, but the feel of the boat is most important in deciding what move to make, and when. After a while, and many runs up the lake and back, I was able to turn at will, still not knowing exactly how. I guess more time at the tiller is required to answer all the questions that arise with a new boat.

The next challenge came in the form of strong winds and gusts. While going downwind, I was sometimes met with gusts that had a tendency to turn the boat. I had to compensate by pulling in the sheet, to maintain course. But the interim time was scary. The boat just took-off, on its own for a moment, and I was the hostage. Remember, the sail area is only 36 square feet on only a 12 foot high mast. This happened more than once, and a couple of times I let it go to see what the results would be. Although I never capsized the boat, it sure seemed to come close at times, with the water only a few inches from the gunwale. To me, the sail is a perfect size for the boat, and my inexperience. Hull speed is calculated to be about 6 knots, but with a strong wind it felt like I was sailing much faster. It was exciting, challenging and humbling all at the same time.

In conclusion, I must say I was impressed with all aspects of the little boat. It is rugged, roomy with plenty of freeboard, and able to withstand the inexperience of a novice sailor. Onlookers at the dock were intrigued by its ability to break-down completely into a package that fits into the bed of a small pickup, especially the nesting of the hull sections and the collapsible mast. The next trip out I hope will be with someone who can take a video of the assembly, launch and sailing of the Pollywog, for your readers pleasure.

Best regards,

Ken Simpso |

|

New Boat

Did you see my new boat?

Charlie Whipple |

|

|

GEORGE WASHINGTON’S SECRET NAVY:

How the American Revolution Went to Sea

by James L. Nelson has been selected as the 2009 recipient of the Samuel Eliot Morison Award for excellence in naval literature. The book is published by McGraw-Hill Professional.

Presented annually by the Naval Order of the United States, the Morison Award is given to the author “who by his published writings has made a substantial contribution to the preservation of the history and traditions of the United States Navy.”

In making the announcement, William Schmidt, Commander of the New York Commandery of the Naval Order said, “This book illuminates a series of little known yet crucial events during the early stages of the American Revolution. It sheds new and badly needed light on the naval component of the War of Independence, a subject often neglected by historians.”

The book’s editor, Jon Eaton, comments, “As James L. Nelson’s editor for GEORGE WASHINGTON’S SECRET NAVY, I’m delighted by the book’s selection for The Samuel Eliot Morison Award. I count myself one of the most enthusiastic among Jim’s legion of fans. He combines a first-class researcher’s instincts for archival sleuthing with the story-telling flair developed in his popular novels of the sailing navies and the first-hand knowledge of the sea absorbed from his work as a ship’s rigger and tall-ship sailor. He knows how to find a great story and how to tell it. I worked with Jim on his previous book, Benedict Arnold’s Navy (2006), as well, and will have the great pleasure of working with him again on his forthcoming book (due in 2010) about the land-and-sea battles at Yorktown that finally decided the American Revolution. He makes an editor’s job easy. I could not be more proud to publish his trilogy of Revolutionary naval histories.”

Patrick O’Brian, author of the Master and Commander, considers Nelson to be “a master both of his period and of the English language.”

Named for Rear Admiral Samuel Eliot Morison (1887-1976), who is ranked among the foremost authorities on American History, It is one of the premier awards of the Naval Order of the United States. The Naval Order was founded in 1890 to encourage naval writing, research, and the preservation of historical materials. Past recipients include David McCullough, Tom Clancy, and former Secretary of the Navy John Lehman.

Author Nelson will be presented with the award at a black-tie ceremony in New York on November 2nd, 2009.

GEORGE WASHINGTON’S SECRET NAVY

How the American Revolution Went to Sea

James L. Nelson

Paperback, $17.95

0071628258 / 9780071628259

For more information about Mr. Nelson, visit his website: https://www.jameslnelson.com/ |

|

The Lowdown on Lower Unit Lubrication

Porter, TX (May 14, 2009)—Conversations about lower unit lubrication don't typically generate much interest around the ramp. That is until someone gets water in their lower-unit and loses a gear case. Royal Purple explains some of the challenges and offers some insight to help you choose the right lubricant.

The Design Challenge

Modern outboard lower units uses spiral-bevel gears designed with a curvature in the teeth. This design distributes the load over several teeth to increase the gear set's load capacity providing smoother, quieter operation. The downside of this design is the increased lubrication demand due to the sliding along the curved teeth. The sliding action increases friction and heat. These extremely demanding conditions require specific lubrication.

The Lubrication Challenge

Spiral-bevel gears require extreme pressure additives (known in the industry simply as EP additives) to handle the strain of increased shock load and high RPMs. It's important that a lubricant has adequate film strength to prevent the metal-to-metal contact that causes heat and wear. Film strength can be measured using American Society for Testing Materials (ASTM) D-2782 Timken Load Test. The higher the film strength, the less metal-to-metal contact. Performance lubricant manufacturer Royal Purple has gained a reputation for developing lubricants that possess very high film strength as exhibited in the chart comparing the results of the leading synthetic gear oil and conventional (mineral oil based) gear oil with Royal Purple's 'Max-Gear' gear oil.

<SEE TIMKEN300DPI.JPG FILE ATTACHED>

Unlike with engine oils, it's important that different gear oils not be combined. If you elect to switch gear oils you should make sure all of the old gear oil is completed drained out before adding the new gear oil. Each gear oil brand formula is unique; mixing two brands will result in a lubricant that inferior to either of the two that you started with.

The Frequency

Most outboard manufacturers recommend changing gear oil annually or every 100 hours (whichever comes first). Some recommended shorter intervals in when in salt water. At least one company, Evinrude, allows up to a 300-hour/3 year drain when using their particular HPF-XR oil. Regardless of the change interval, any accidental introduction of water into the system demands immediate attention.

Water - The Unseen Enemy

Water in an outboard's lower unit often goes undetected until it's too late and expensive repairs are needed. One of the most common causes, particularly among anglers, is discarded monofilament line, which gets wrapped around the prop shaft and damages seals.

When water and oil are violently mixed, the emulsified mixture dramatically reduces the gear oil's ability to do its job. A lubricant's ability to rapidly separate from water indicates how well it will continue to lubricate should water be introduced to the system. Regardless of how well and quickly a lubricant separates from water, it should be changed immediately if water enters the system. The chart below indicates how well the candidate gear oil separated from water when compared to the leading synthetic and conventional gear oils.

<SEE WATER SEPARATION ILLUSTRATION ATTACHED>

No one would ever want or plan on having water contamination in their lower unit. Spending a few extra dollars for the extra protection from a high quality gear oil is likely worth the peace of mind.

About Royal Purple

Royal Purple makes synthetic products for numerous automotive and consumer needs. For more information on Royal Purple or its products, contact Royal Purple Inc., One Royal Purple Lane, Porter, TX 77365, 281-354-8600, www.royalpurple.com.

### |

|

| Graphite and Teflon (tm) additives for Epoxies

Pittsfield, NH - (6/09) - Progressive Epoxy Polymers, Inc., an internet supplier of epoxy resins/coatings, urethanes, fillers and thickeners for commercial, residential and marine use, is offering both graphite powder and Dupont's Teflon(tm) powder for use with epoxy resins.

Both products are often used to reduce friction in areas where epoxy coatings rub against another surface, such as such as a centerboard pivot pin in small sailboats.

The graphite (sold in 1 pound/1 quart units - $14) is sometimes used also as an epoxy pigment. When mixed with epoxy it produces a ‘midnight gray’ shimmery color. The Teflon (tm) is a fine white powder that mixes/suspends easily into the epoxy. As the epoxy wears or weathers, fresh Teflon is exposed. $30 for one half pound.

Visit PEP’s web site at: www.epoxyproducts.com

data and msds at: www.epoxyproducts.com/datamsds.html

contact: Paul Oman - info@epoxyproducts.com -- --

============================================

PAUL OMAN Progressive Epoxy Polymers, Inc. Incorporated -- State of New Hampshire Office hrs 10:30-3PM Mon-Thur closed Fridays info@epoxyproducts.com 603-435-7199 www.epoxyproducts.com --- www.epoxyUSA.com VISA//MC/Discover/AMEX/Paypal

============================================

|

|

|

|

|

|