|

One-Sheet Baby Canoe

Part 1 |

|

| By Gaetan

Jette - Sherbrooke, Canada |

Part

1 - Part 2

- Part 3

- Part 4

Introduction

It is often recommended, for first

time boatbuilders, to start with a small project.

That's one advice I followed: I built a one-sheet

boat. Both the building and storage space available

to me could not handle anything much bigger anyway.

Designing your own boat, however, is

not recommended by experts. Well, since I am as much

interested in the design process as in using that

boat, I couldn't resist the challenge. My thinking

was, this would be a great learning experience, and

if the boat proved to be a failure, the investment

in time and money would not have been too great. The

project took 2 years to complete: one year to draw

it, one year to build it. That took longer than expected,

but I didn't fully know how to draw a boat when I

started this project. In particular, I had to learn

how to do a surface development for the hull. As for

the building, the sanding took forever, it seems.

I am pleased with the way the boat

looks. Performance wise, though, it is quite tippy,

at least for a novice paddler like me. But it was

a great learning experience.

History

of the design

I did not wake up one day and just

decided to build a one-sheet canoe, though. What happened

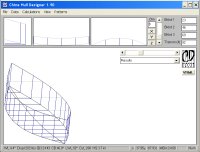

was this: a few years ago, I started to play with

Gregg Carlson's Hull Designer program. During the

same period, there were quite a few one-sheet designs

presented on the Duckworks web site. I thus chose

to learn that program by concentrating on a one-sheet

double-ender. Why a double-ender, do you ask? Well,

first, this is an easier design to figure out. If

the crew sit right in the middle, you get perfect

trim. Since, as far as I know, the Hull Designer program

doesn't adjust trim, this was easier to deal with

than on a transom boat. Second, maximizing the length

of the bottom and side panels seems easier if you

don't have to also fit a transom on that single sheet.

Third, I was aiming more at good gliding performance

rather than the highest displacement possible, as

with a pram shape.

The first hull looked like this:

|

|

Simple

flat-bottom double-ender |

This is essentially a flat-bottom hull

with vertical top sides. That's about the simplest

shape there is for a boat: all the curves are basically

circle arcs. The reason for using vertical top sides

without any flare was to achieve maximum waterline

length. With some flare, the chine is typically shorter

than the sheerline. The sheer curve is achieved by

drawing a curved plank, rather than using a mostly

straight plank with a good amount of flare.

Although such a hull shape doesn't

look too bad, it is hard to achieve a fair displacement

and adequate freeboard at the same time. I decided

to go from a flat to a V-bottom, to see if this would

increase displacement. I also started to make cardboard

models of the most promising models, using empty cereal

boxes.

The hull shape did look a bit better,

despite being drawn with vertical sides. The displacement

was a bit better but still too low: my target was

250 pounds. More rocker in the bottom would have been

necessary to keep the stem above the waterline. But

this would have meant less freeboard amidships. As

a novice designer, I wasn't sure how much freeboard

was enough, but more seemed better.

I decided then to got for a second

chine, hoping for better results. I tried several

variations of plank shape for the new middle plank.

The one variation that seemed to go somewhere was

this one:

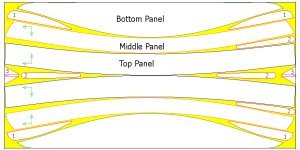

By making the middle plank narrower

in the center and wider at the extremities, this left

more plywood for the midship area of the bottom planks.

This also flattened the keel line, burying the stem

somewhat underwater. This would be bad for a flat-bottom

boat, but good for a multi-chine hull. This improves

tracking and adds a little more displacement. The

shape was starting to look a lot like a canoe. It

is at that point that I decided to seriously attempt

to draw a canoe.

The middle plank was quite narrow on

this model, looking more like it was just softening

the edge of a hard chine hull. For the next model,

I decided to use a wider middle plank. I looked more

seriously at optimizing the midship cross-section.

Hannu Vartalia's online essays, in particular, come

to mind. I also checked what were typical dimensions

for a canoe. An online version of W.P. Stephens' book

'Canoe and Boat Building' proved useful for that.

It might have best to go look at real canoes, though.

I might have noticed that typical canoes have a flatter

midship section than what I was drawing. Anyway, the

next model looked this:

All that was missing for an authentic

canoe look on this model was a round stem/stern and

a round bilge. The round bilge couldn't be done in

plywood, as far as construction was concerned. The

round stem, I couldn't do using Hull Designer. You

can approximate the rounded look by creating multiple

chines, but that program, as far as I know, is not

suited for drawing perfectly round stems (you can't

ask too much from a free program). At that point I

moved to another program for drawing my hull models.

I used TurboCAD, a general purpose drafting program

I was somewhat familiar with. I say somewhat, because

although that program can handle drawings in 3D, I

was not comfortable with the 3D interface of the program.

Instead, I drafted my next hulls in 2D, much like

the way hulls lines are drawn on a sheet of paper.

This meant much slower progress, having to deal with

surface development manually. One book, by S.S. Rabl,

titled "Ship and Aircraft Fairing and Development"

proved helpful to understand the process, which previously

was a mystery for me. It nevertheless took several

drafts, due to various mistakes and problems, before

I could build a cardboard model.

The round stem gave me some trouble:

a surface can be developed if it bends in one direction

only. With a hull shape created by an arc lengthwise,

near the bow the plywood would have to bend both horizontally

and vertically: not possible. The solution was to

use an arc for most of the boat length, but finish

the last 9 inches near each end with a straight line.

This way the surface would end up closer to what plywood

can handle: it would only have to bend vertically

to follow the curved stem.

The stem curve was achieved by using

a portion of an oval shape, with a straight section

for the top plank. That curve looked fine in profile,

but the lower part of the bow seemed too full, especially

when looking at the model. If you look closely at

the hull lines, in the profile view, the bottom chine

is almost a straight line. It didn't look too bad,

but it certainly looked odd in profile view. I thought

it would be best to raise that chine near the bow

and stern. A couple drafts later, I had arrived at

this:

I built the model on a larger scale

this time: I printed the pattern on paper and glued

them on cardboard. The keel, frames and gunwales were

cut from 1/8th inch plywood. At this scale, this was

equivalent to 3/4-inch stock. I even made a wooden

support and a double paddle. I broke 3 gunwales on

that model before I succeeded to fit them. I only

managed to fit them by starting from the middle, and

then bending gradually toward each end. In the previous

attempts, I had started at one end, bending toward

the other end, with breakage occurring about 3 quarters

through. I can't explain why the gunwales reacted

that way, but I kept this trick in mind for the full-size

build. I also decided to use half-inch thick material

for the full-size gunwales.

I was happy with the look of that boat,

at first. Then, after a while, a little detail bothered

me. Although the top and middle plank were ending

smoothly on the bow and stern, the bottom panel seemed

to have a bit of a bulge in that area. I didn't know

what to do next to correct that problem. I looked

back at my drawings, and eventually an idea emerged.

Looking at the end view, the chine angles used for

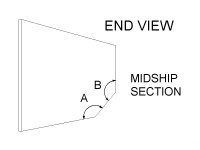

the midship section were equal:

|

Chine

angles A and B are equal for the midship section |

What if the chine angles for each and

every station were equal? So far, they were not. The

difference in chine angle value just grew as you got

near the bow or stern. The drafting process had been

going a bit like this:

- Draw a midship section in the end view

- Draw a keel in the profile view

- Draw circle arcs for the sheer and chines

- Fit the stations to fit the sheer and chines

just drawn

-

With a twisted V-bottom, if I used

equal chine angles on all stations, the angle values

would be different for each station. The drafting

process would have to go a bit like this:

- Draw a midship section in the end view

- Draw a keel in the profile view

- Draw circle arcs for the sheer and top chine

only

- Draw lines for the bottom and middle planks

for one station

- Measure the chine angles

- Redraw until the top and bottom chine angles

are a close match

- Repeat for all other stations

Doable but tedious. I didn't have a

simple way of doing the task. I remembered a way to

draw a boat using circles I saw on a web page here.

I didn't know if that method could solve my problem.

It was based on an Excel spreadsheet, a program I

didn't have on my PC.

I played with circles and found a way

to use them that work, but not 100%. The last couple

stations still had to be done by trial and error.

Here is a pictorial description of how I did it.

|

Click to enlarge |

Step

1- First, because the top plank is vertical

(mostly), the sheerline and top chine are drawn

in the plan view. The top segments for each

station can then be drawn. The area between

stations 0 and 2 is where the sheer, in the

plan view, changes from an arc to a straight

line. (Same thing between stations 14 and 16) |

|

Click to enlarge |

Step

2- Starting with the midship station (section

8), a circle (in blue) is drawn with 3 points

touching the top chine, bottom chine and the

lowest point on the keel. A copy of this circle

is placed with its center on the lower chine

point (dotted blue circle). A line (in blue),

placed at the edge of this second circle, is

drawn perpendicular to the bottom plank line.

Its length is delimited by the first blue circle.

Now, for a different hull shape, a different

position for that blue line would have to be

figured out. On the enlarged picture, red dots

show the circle's 3 points. |

|

Click to enlarge |

Step

3- Section 7. A 3-point circle is drawn (in

green) with 2 points touching the extremities

of the blue line previously drawn and the third

point touching the top chine at this section. |

|

Click to enlarge |

Step

4- Section 6. A circle is drawn (in orange)

in the same way as the previous circle. |

|

Click to enlarge |

Step

5- Section 5. A circle is drawn (in turquoise)

in the same way as the previous circle. |

|

Click to enlarge |

Step

6- Section 4. A circle is drawn (in yellow)

in the same way as the previous circle. |

|

Click to enlarge |

Step

7- Section 3. A circle is drawn (in gray) in

the same way as the previous circle. |

|

Click to enlarge |

Although

circles can be drawn (in brown and dark green)

for Section 1 and 2, the angle values achieved

for the top and bottom chines are no longer

close, probably due to the strong curve of the

stems. Those last 2 sections have to be done

by trial and error. |

One beauty of this "trick" is that

it automatically creates the curve for the keel. This

trick is still a work in progress: the 2 intersection

points for all circles were chosen by trial and error.

For a different hull shape, such as less deadrise

for the bottom, the position of those 2 points (the

ends of the blue line in this example) would be different.

A mathematician could probably perfect that trick,

but I am not one. What matters is that method worked

well enough to finish the last draft of my boat.

Did making the chine angles equal produce

a fair looking boat? I think so. As a bonus, this

new "rule" introduced just a little bit of hollow

in the lower chine, near the bow and stern. Although

the difference with the previous draft is subtle,

it definitely corrected the bulge problem on the bottom

plank. I now had a fine entry I was happy with.

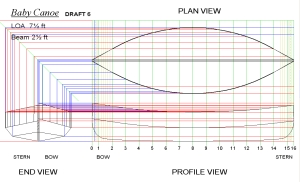

This is what the plywood sheet layout

looks like:

|

Click

to enlarge

1.- Paddle (half)

2.- Paddle center plate

3.- Breasthook |

As you can see, there is not too much

waste. In fact, even the waste area (in yellow) will

be put to use. Splitting the paddle blades in half

allowed to squeeze them in. The only additional wood

required will be for the keel, inwales, outwales and

seat. Plus the temporary frame and backbone used during

construction. Below is an illustration of the construction,

with the breasthooks removed to show more construction

details.

|

Construction

(Click to enlarge) |

Here is a comparison between my design,

that I called Baby Canoe due to its diminutive size,

and a typical cruising canoe, according to W.P. Stephens.

| Dimensions |

Typical

Cruising Canoe |

Baby Canoe |

| LOA |

14 ft |

7-1/2 ft |

| Beam |

30 in. |

30-1/2 in. |

| Hull depth at bow |

18 in. * |

17-1/2 in. |

| Hull depth amidships |

12 in. * |

13-3/4 in. |

| Hull depth at stern |

16 in. * |

16-1/2 in. |

* Numbers obtained by adding Freeboard plus Draft |

While I was approaching the end of

my drafting efforts, I finished reading an article

that was bad news for my design. According to that

article, a deadrise of 5 degrees is suitable for a

stable boat, 10 degrees being on the sporty side.

My design has 11 degrees. I knew that too much deadrise

would mean an unstable boat, I just didn't know how

much was too much. Now I knew. So I said to myself,

ah well, it's gonna be a tippy boat. If I wanted to

start building that year, it was too late to redesign.

The hull shape of my design would be best suited for

a keel boat perhaps, but my budget and space allowed

only for a canoe, so a canoe it is.

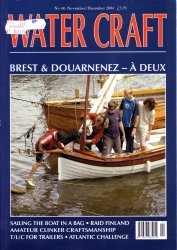

|

According

to an article in this magazine, my boat will

be tippy, err, sporty. |

That's it for now. Stay tuned for the next part,

where we will begin construction.

On to Part

2

REFERENCES

SOFTWARE

|