|

|

|

|

|

One-Sheet

Baby Canoe Part 3 |

|

| By Gaetan

Jette - Sherbrooke, Canada |

Part

1 - Part 2 -

Part 3 - Part

4

Construction

Continues

Last time, the hull took shape and

work on the paddles progressed. But the boat building

still has a long way to go.

|

Time to complete

the inside fillets where the frame once was.

A second layer of tape is then applied on each

side of the keel, overlapping the first layer.

|

|

That new tape

along the keel and the chine fillets are then

faired with thickened epoxy. |

|

There were a

few air bubbles in the stem inside fillets.

I drilled a small hole at the top and bottom

of each bubble. I then poured clear epoxy with

a dropper through the top hole, till the cavity

was filled. Not as strong as thickened epoxy,

but better than a void. |

|

I cut a 2x6 into

half-inch thick slices for use as gunwales.

The process left me with thinner slices, some

a quarter-inch thick, some less. I used the

1/4-inch thick slices to laminate the curved

seat braces. |

|

Time to let go

of that "Viking" look: a ruler is used to mark

where the stems will be cut. (Nothing wrong

with Viking ships: it's just not what I am building

this time.) |

|

With masking

tape protecting the top plank, a hand saw is

used to cut the stem. |

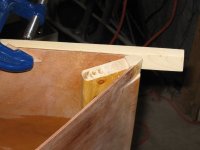

A man never has too many clamps: I had to install

the inwale spacers in several stages. Spring clamps

are not the ideal choice for this. My epoxy batch

was perhaps a little too thick for gluing: the

wood blocks had a tendency to slip under the limited

pressure of those clamps. I had to use two clamps

on each piece. Even then the pressure was not

perfectly even from block to block. This caused

uneven thickness once the epoxy cured.

A man never has too many clamps: I had to install

the inwale spacers in several stages. Spring clamps

are not the ideal choice for this. My epoxy batch

was perhaps a little too thick for gluing: the

wood blocks had a tendency to slip under the limited

pressure of those clamps. I had to use two clamps

on each piece. Even then the pressure was not

perfectly even from block to block. This caused

uneven thickness once the epoxy cured. |

|

|

The

top of the stem has to be trimmed, except for

the tip. The breasthook will rest on the trimmed,

inside portion of the stem. A cleat, extending

beyond the stem, allows to do most of the trimming

with a router. The cut is finished off with

a chisel. |

|

All regular inwale

spacers are now in place. |

|

The end of summer

is here and everybody is asking when

the boat is going to be finished. |

|

The seat frame

is assembled by using dowel pins. It is best

to use a Forstner drill bit for the dowel holes:

a regular twist drill bit will chip the perimeter

of the hole a lot. I learned that the hard way.

|

The gunwale is installed in place, starting from

the middle. That's what worked best on an earlier

model of the boat. A dry fit is done first: spring

clamps hold the gunwale while the screws are driven

in place. This leaves you with screw holes that

make for a speedier assembly the second time,

once the epoxy has been spread. Screws are coated

with beeswax so they can be removed once the epoxy

has cured.

The gunwale is installed in place, starting from

the middle. That's what worked best on an earlier

model of the boat. A dry fit is done first: spring

clamps hold the gunwale while the screws are driven

in place. This leaves you with screw holes that

make for a speedier assembly the second time,

once the epoxy has been spread. Screws are coated

with beeswax so they can be removed once the epoxy

has cured. |

|

Screws could

only be used where there were inwale spacers

(they were driven right in the middle of those

spacers). Clamps had to be used in the breasthook

area. |

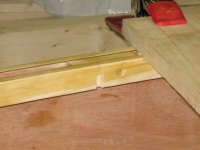

To avoid a hull bent to one side, both gunwales

have to be installed at the same time, before

epoxy has set. In order to fit the second gunwale,

the first gunwale has to be cut: anywhere in between

the 2 lines shown here will do. The left line

is the path that the second gunwale will follow.

The right line, perpendicular to the boat length,

is the shortest the gunwale can be cut.

To avoid a hull bent to one side, both gunwales

have to be installed at the same time, before

epoxy has set. In order to fit the second gunwale,

the first gunwale has to be cut: anywhere in between

the 2 lines shown here will do. The left line

is the path that the second gunwale will follow.

The right line, perpendicular to the boat length,

is the shortest the gunwale can be cut. |

|

A screw in the

second gunwale helps to retain a cleat in place,

giving the spring clamp something to hold on.

|

|

With no screws

in the breasthook area, there is a risk that

the gunwales will slip while the glue cures.

It did so on the bow. If I were to do it again,

I would add one more screw, with a temporary

wood block on the inside. |

|

An improvised

jig is used to trim the tip of the gunwales

with a router. |

|

|

The

tip of the gunwales is trimmed flush with the

stem. |

|

|

A

round pattern is traced on top of the gunwale

tips (a bottle cap of suitable size). The tip

is then rounded freehand with a sanding block.

|

Weather was now too cold for epoxy work in my brother's

shed. Time to move back at my workplace. Do I have an

accommodating boss or what?

|

|

The

breasthook is dry fitted and the cleats underneath

are scribed for their final cut. |

|

The final inwale

spacers, cut at the proper angle, are glued

in place. The angle in question is a vertical

cut: a short flat spot on the bow stem allowed

me to level the boat. Then I could mark those

cuts using a small square with a built-in level.

|

The inwale spacers are one-half inch thick. The

seat brackets are one-quarter inch thick, so a

shim is needed where the seat brackets will be

bolted. I glued quarter-inch thick blocks for

that purpose. This proved tricky to work around

when finishing . A quarter-inch thick rubber washer

would have worked just as well without getting

in the way while applying finish and sanding.

The inwale spacers are one-half inch thick. The

seat brackets are one-quarter inch thick, so a

shim is needed where the seat brackets will be

bolted. I glued quarter-inch thick blocks for

that purpose. This proved tricky to work around

when finishing . A quarter-inch thick rubber washer

would have worked just as well without getting

in the way while applying finish and sanding.

|

|

The center of

the boat has to be braced to its final beam

when dry fitting the breasthook. |

|

The previous

bracing would have got in the way when fitting

the inwales, so a different approach is used

next. |

|

The temporary

outwales used when doing the epoxy fillets are

recycled and used as inwales. As a bonus, they

are almost bent in shape. |

|

The inwales are

dry fitted and marked for the final cut. |

|

Epoxy is applied

and the inwales are screwed in place. |

|

A notch is cut

for the center cross brace. This brace is placed

just behind the seat. The inwale spacer behind

it is 3 inches long. All the other inwale spacers

are 2 inches long. |

The center cross brace is made up of several laminations,

1-1/2 inch wide, then rounded with a router using

a half-inch rounding bit. This produces a very

comfortable grip. The longer bottom section will

sit against the bottom of the inwale. A loose-tongue

joint is used for assembly. Two layers of plywood,

taken from the plywood sheet waste area, form

the tongue. The groove in the cross brace is routed

with a quarter-inch bit. Since the tongue and

groove don't go all the way to the top, they won't

be visible (unless you are very curious!).

The center cross brace is made up of several laminations,

1-1/2 inch wide, then rounded with a router using

a half-inch rounding bit. This produces a very

comfortable grip. The longer bottom section will

sit against the bottom of the inwale. A loose-tongue

joint is used for assembly. Two layers of plywood,

taken from the plywood sheet waste area, form

the tongue. The groove in the cross brace is routed

with a quarter-inch bit. Since the tongue and

groove don't go all the way to the top, they won't

be visible (unless you are very curious!). |

|

|

The

seat brackets that will support the seat frame

are made from one-inch wide, one quarter-inch

thick aluminum bar. They are bent using a home-brew

bending jig. The bar is bent around the 2-inch

pipe, which is held in place with a few screws.

Two flat bars act as levers, rotating a bed

wheel that pushes against the aluminum bar.

This worked... barely. The 2x4 supporting the

bed wheel was twisting under tension, due to

some play in the screw holes. L-shaped bars

would have worked better. |

|

It is hard to

achieve a perfect 90-degree bend with the bending

jig. It is possible to do small adjustments

in a vise. |

|

All the cross

braces are now in place. |

|

The breasthook

cross braces are notched, so that the breasthook

plate is supported all around. The width of

that notch is chosen so that the visible portion

of the cross brace is one-half inch thick, just

like the gunwales, for a more harmonious look.

|

|

The breasthook

plate is glued in place, using spring clamps.

|

|

This is how the

completed bow (and stern) look. |

|

Dry fitting the

seat frame and brackets proved a little bit

tricky. I first tried to prop everything in

place by using shimming blocks under the seat

frame. |

|

|

I

then built a jig, for easier testing and adjustment.

|

Once

the gunwales were glued, the screws used during

assembly were removed. Now, the screw holes are

enlarged with a 3/8-inch Forstner bit. Dowel rod

will then be set in those holes, for a more decorative

look. Achieving perfect center alignment on both

sides of the gunwales would be too difficult,

if drilled through completely. Instead, I drilled

through the outwale till I reached the plywood,

then I drilled through the inwale, again stopping

at the plywood. So two sections of dowel rod are

needed to plug each pair of holes, but the result

will look as if there is only one rod going right

through. Once

the gunwales were glued, the screws used during

assembly were removed. Now, the screw holes are

enlarged with a 3/8-inch Forstner bit. Dowel rod

will then be set in those holes, for a more decorative

look. Achieving perfect center alignment on both

sides of the gunwales would be too difficult,

if drilled through completely. Instead, I drilled

through the outwale till I reached the plywood,

then I drilled through the inwale, again stopping

at the plywood. So two sections of dowel rod are

needed to plug each pair of holes, but the result

will look as if there is only one rod going right

through. |

|

The dowel rods

have been cut a bit long and glued. The empty

holes are for the seat bracket bolts. |

|

|

A

hand saw and some masking tape allow to trim

the dowel ends as flush as possible, without

damaging the gunwales. |

Around this point, I was so fed up with sanding, I took

a long break. It was also obvious that the boat would

never be finished for Christmas. For most of December

and January, I did practically no work on the boat.

The bow and stern area (inside) proved the most

difficult part to sand smooth. I should either

have used something wider when spreading the epoxy

for these fillets, or made the stems narrower.

This would have avoided that narrow groove that

took forever to finish sanding. The inside of

the breasthook was no picnic either. I was perhaps

too perfectionist: I certainly cannot blame people

who settle for a workboat finish.

The bow and stern area (inside) proved the most

difficult part to sand smooth. I should either

have used something wider when spreading the epoxy

for these fillets, or made the stems narrower.

This would have avoided that narrow groove that

took forever to finish sanding. The inside of

the breasthook was no picnic either. I was perhaps

too perfectionist: I certainly cannot blame people

who settle for a workboat finish. |

|

It took much

longer than expected, but now the hull is now

ready for paint and varnish. |

|

This is the type

of bolts used for the seat brackets: they are

called connector bolts, normally used for furniture.

Because the gunwale is curved, the holes for

these have to be recessed a bit for their large

head to rest flat. The two bolts shown here

have been gouged to become an exact fit cutting

tool. |

|

Varnishing the

gunwales. I used a roll of wax paper to cover

the sides. |

|

After the paddle

blades have been faired a first time, fiberglas

cloth is wrapped around the edge of the blade

to improve resistance to damage. Masking tape

is used to ensure the cloth stays flat against

the blade. |

|

The fiberglas

cloth has been covered with clear epoxy. A few

wrinkles are unavoidable. |

|

Areas of the

cloth previously covered with masking tape did

not absorb epoxy much. These have been cut off

and a rough sanding removed any excessive bump.

|

|

One coat of lightly

thickened epoxy is applied to the blades. |

|

One blade is

now fully sanded. One more to go. |

That's it for this time. Next time the building

will be completed and the boat launched!

|

|

|

|

|

|