| Send

items to chuck.leinweber@gmail.com

for inclusion here next month.

The Treasure Chest

The Treasure Chest is a place in Reports to put those

cool sailing, cruising, motoring, boatbuilding or boating tips

you have. Send us your ideas... We just need a photo and a short

description.

This time we have...

How to Make a Name Plate

Step 1 Choose a name

Step 2 Choose another name (or have another one

chosen for you).

Step 3 Go through the list of 300 names you have

chosen and argue about it for a while and then settle on a final

name.

Step 4 Pick out your name plate (Here I have a piece

of pine which I will trim down in size later)

Step 5 Print out the name you have chosen in a size

befitting the name plate, in a font befitting the name. For the

Ollie Punt I used Gabrielle.

Unfortunately, if you let yourself go on the internet

looking at places like www.dafont.com,

picking a font is almost as difficult as picking a name.

Step 6 Cut the name out of the paper and glue it

to the name plate using a cheap/water soluble glue like a glue

stick.

Step 7 Take a rotary tool or a set of carving tools and cut out

your choice of either the black bits or the white bits. Being

lazy, I carved away the black bits.

Step 8 Wash, sand or scrape off excess paper.

Step 9 Tidy up, trim, decorate and paint. I used

a bit of pencil to darken in the carving and a bit of varnish.

Step 10 Attach to boat.

Step 11 Put boat in water.

Step 12 Put person in boat.

Yes, it is a white Ollie Punt.

Ian Titulaer

Using Masking Tape When Fibreglassing

Warren Messer has a great tip for fibreglassing. He lays down

a line of masking tape to give a clean edge to the glass when

finished. You put the masking tape down so the fibreglass overlaps

the masking tape. Fibreglass normally but, while the glass is

still green, run a knife along the edge of the glass at the masking

tape line. Remove masking tape and excess glass. You are left

with a rough edge which can be easily removed. Here is his video

on how to do it:

Warren's plans are available at Duckworks here.

The rest of Warren's videos are here.

Tender Behinds in England

Retired airline Pilot and small boat enthusiast

Mike Austen is busy building two stretched to 8ft long Tender

Behind sailing dinks , one for himself, and one for Daughter Sherry.

His one will eventually become the tender for a bigger boat planned,

but in the meantime, to avoid the snow and sleet that covers his

backyard near Bristol UK he has brought TB number one into the

conservatory at the back of his house, and is contentedly getting

on with the build of number one.

He sent me two pics of the boat as at today, Sherry wanted to

see how it felt in the boat so has climbed in. While the wide

angle lens on the camera does odd things to the proportions Mike

is already getting compliments about the looks and the amazing

amount of space in such a small boat. As we sell a lot of Tender

Behind plans I figured that it was worth showing the little boat

off and mentioning that for those interested in the design He’s

documented the build on his website at https://www.backyardboatbuilding.org.uk/

.

John Welsford

Regatta at Lake Arthur

"Events for Puddle Duck Racers will be included in this year’s

Regatta at Lake Arthur, to be held on August

7-8. The lake can be found in Moraine State Park some 25 miles

North of Pittsburgh. The traditional "Anything That Floats" event

will be modified this year in that entries will be based on Puddle

Duck Racer Hulls and there will be prizes for beautiful, artistic

or outrageous additions to the basic hull. There will also be

a race with a "Le Mans Style" Start. For further information or

notification of intent to participate, please contact the Butler

County Tourism & Convention Bureau. joey@visitbutlercounty.com

You are invited to enter these events, watch the Saturday evening

fireworks, generally join in the fun and enjoy all that this Pennsylvania

Park has to offer. Several nearby campgrounds are available."

The plans for the PDRs below are available at Duckworks. Jim

Michalak has just finished his PDR Catbox

plans with a lateen rig.

Long Tail

Picture taken on a motorcyclist's trip thru southern

India.

Bruce Armstrong

Finally done the Drake

I have completed making David Beede's OS John boat from the

Simplicity Boat's page. This boat I call the Drake and it has

given me a tough time. Now that it's done, I like it a lot.

https://www.flickr.com/photos/47291288@N07/

Lessons learned;

1.) Don't buy the cheap 3 layer luan plywood even though it is

marked as "Moisture resistant" - it is not. I refer

to the very lightweight luan for $10.99 a sheet with 2 thin layers

of veneer sandwiching some type of soft spongy material that seems

like balsa or pulp. Spring for the $19 per sheet premium underlayment

warranted for 25 years.

2.) Don't try to build a ply-on-frame jon boat from stitch-n-glue

plans. The compound angles where the front transom and sides and

bottom come together are impossible to calculate. This type of

shape should be kept stitch-n-glue.

3.) Do apply a basic camo paint job, makes you want to awaken

your inner sportsman

4.) Do buy some new fishing gear and a cooler.

Thanks

Kenny in Philly

Proa

Hi Chuck!

I'm back! I am sending you some photos from the transportation

from my garden. Thanks to good neighbors, it worked perfectly.

I hope the pictures are good.

Greetings Willi

Boat building...

Lucas Boatworks and Happy Hour Club

I apologize for this flurry of emails lately. A

lot of things are going on here at the shop that interest me so

I assume you'll be interested also. First is the 20 ft kayak that

Sam just finished. This is one slick boat. There's no substitute

for hull length, that's what Sam said when I told him how easily

this boat slipped through the water. It's also very stable, you

can step into it without tipping over. Things slowed down after

the bear got in but it still went very well. Abigail is a big

yellow Lab who's on a green bean diet to get her slim figure back

by Cedar Key. This boat will be at Cedar Key on May 1 along with

all of you. Next is Helen Marie hanging up ready for the inside

glass job.

Dave

David Lucas

Lucas Boatworks and Happy Hour Club

(941) 704-6736

Lissa

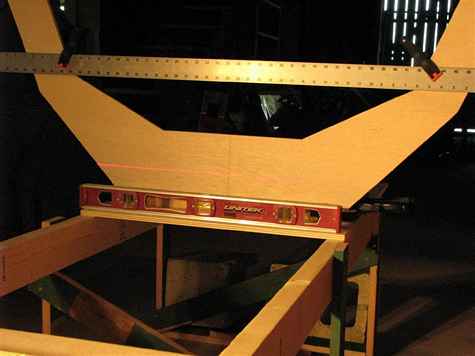

Since December, we have been working on Lissa/Otter.

The picture below is the most recent. As you may recall, I decided

to used the dimensions and scantlings from Lissa

but the more current all plywood construction as in Jacques Mertans

Otter.

Instead of the timber frames that Lissa

shows, you can see that I used plywood. I used the 6 oz diagonal

bias tape on the seams and 12 oz diagonal bias fabric on the hull

inside. This schedule is very similar to the Vagabond. I am using

the System 3 resin and also QuikFair, both nice products. We are

building the boat in an unheated barn and the cold temperatures

slowed up the building process. I hope to finish before the temperatures

get excessively hot.

With suggestions from Jacques Mertans, I decided

to construct the boat in a basket mold. I first used the mold

technique to build Pepita

and then again for Just Right. This time, I made use

of a laser level to set up the frames. Now that I am nearing the

halfway point, errors usually build up. I am amazed that the frames

and panels are still level and plumb as close as I can detect

with a bubble level and tape. I expect that if I had just cut

and taped I might be farther along. I was able to construct the

mold in a little more than a weekend. It places the boat at a

convenient working level and makes cutting all those extra parts

easier.

Looking at the picture, I have a hard time remembering that Lissa

and Pepita have nearly the same mid

cross-section. Lissa looks a lot bigger.

As you remember, I submitted an entry in the

Duckworks Puget Sound Cruiser contest which

was based on the Lissa. This is a chance

to validate my submission.

I really appreciate the fine quality of Joe Dobler's plans. I

can tell that he thought through lots of the details. Since Joe

built the boat and kept it many years, I think he liked the end

product.

BTW, I see that you added a B&W photo of assembling the Pepita.

Unless I am mistaken, the bald guy is Joe and the young journeyman

is me. I liked the write-up.

Justin Pipkorn

Clint

Chase Boatbuilder

US Agent for François Vivier Architecte

Naval;

Brings CNC Boat Kits to New Boat Builders

Portland,

Maine –Clint Chase is pleased to announce that Clint

Chase Boatbuilder will now be a US agent for precision

cut boat kits for François Vivier, a prolific designer

of ships, yachts, and traditional small craft in

France. Additionally, Clint Chase is contracting

with other designers around the world to bring new

boats and CNC (Computer Numerically Cut) boat kits

to our market for the first time. Vivier’s design

work is iconic in France and other EU countries

and is bound to become equally iconic to the wooden

boatbuilding and boat kit industry in North America.

We

are also providing CNC kits to designs by Michael

Storer, from Adelaide, Australia, Eric Risch, from

Gardner, Maine, and we are in talks with designers

in the UK, Finland, and New Zealand. CNC cutters

in Maine will be employed to cut the kits and ship

them by freight. Cutters in North Carolina and soon

Texas will also be employed in the greater effort

to get kits into the hands of builders around the

country.

Clint

has been cutting kits for several months, but is

impressed by the interest in CNC boat kits by potential

customers, the wooden boat community, and designers

whom he has contacted. About a recent kit delivery,

a customer in Houston, Texas said, “[the Goat Island

Skiff] is a very nice kit overall. I looked at the

wood grain pattern of the tank tops and transom,

a very nice selection! The crate shows that you

care about the things you build. Everything was

well packed and labeled.”

"I

applaud Clint's approach to bring international

boat designers' kits to the North American market.

There are so many creative ideas for small boats

around the globe and Clint is approaching this in

just the right way. We all wish him well. At the WoodenBoat Show[www.thewoodenboatshow.com]

this year (June 25-27, at Mystic Seaport, CT), we

are taking a new approach to Family BoatBuilding [www.familyboatbuilding.com]. For the first

time, we will be inviting independent kit-producing

companies to exhibit and to teach families and groups

how to build their own boats. Clint was one of the

first to contact us, and we are delighted that he

will be building the Echo Bay Dory Skiff with a

number of families. Clint is the consummate teacher,

and we are excited to have him helping us."

---Carl Cramer, publisher of Wooden Boat Magazine

and Professional Boatbuilder

Clint

Chase is a graduate of The Landing School of Boatbuilding

and Design in Kennebunkport, Maine. He started Clint

Chase Boatbuilder after four years running youth

boatbuilding programs. The three pillars of the

business are: ultra-light, wooden masts and spars

(“Birdsmouth” spars for sailboats), custom wood

and composite oars, and precision-cut, CNC Boat

Kits. In the US, there is a growing popularity and

demand for CNC plywood kits for exceptional motor,

sail, and rowboat designs from 8-28 feet. However,

there are only a few kit providers in the market

from which customers can choose and none that are

reaching out to designers abroad to bring their

beautiful boats to the US market. For more information

please visit clintchaseboatbuilder.com and come see our exhibit (building

#2, display 19) at the 2010Maine Boatbuilders

Show [www.portlandcompany.com/boatShow/]

(March 19-21st at The Portland Company Complex in

Portland, Maine).

|

Birdsmouth

Masts & Spars |

Custom

Wood and Composite Oars |

CNC

Boat Kits for row, sail, and power boat |

DuraSafe Coupler Connect

Product of the Week: DuraSafe Coupler Connect™

Friday March 5, 2010

DuraSafe Coupler Connect™ is an easy-to-use trailer alignment

device that also offers optional protection against accidental

trailer uncoupling.

Coupler Connect™ eliminates the problems many people have

with trying to hook up a trailer by locating the trailer coupling

directly over the ball without the need of assistance –

and prevents damage to the tow vehicle. A unique mounting bracket

(fits standard 1” diameter ball shanks) accommodates a wide

range of couplers and ball mounts and allows for maximum turning

radius. MSRP $39.99.

DuraSafe Coupler Connect™ plus Protect offers the same

advantages as the Coupler Connect but also includes a separate,

universal-fit hold down device that prevents the coupler from

accidentally popping off the tow ball during travel. 1.) Use the

guide plate accessory to align the coupler directly over the tow

ball for easy hookup. 2.) Remove the guide plate and insert the

protective hold down accessory to help prevent the coupler from

accidentally popping off the tow ball during travel. The guide

plate can also be used to secure the trailer to the tow vehicle

when a padlock is used. MSRP $54.99.

More info: www.durasafelocks.com

or call 1+262.544.5615.

DuraSafe – 1785 S. Johnson Road – New Berlin, WI 53146

USA

New Fiberglass Boat Repair Book

Fiberglass Boat Repairs Illustrated

comprehensive guide

to major & minor repairs, finishing & painting

JAMESTOWN, RHODE ISLAND (USA) – Fiberglass

Boat Repairs Illustrated, available at chandleries,

bookstores and online this month, is a comprehensive guide to

making repairs to a fiberglass boat and how to finish and paint

those repairs.

Written by Roger Marshall, winner of numerous awards for marine

technical and magazine writing and author of 14 nautical books,

the nine chapters of Fiberglass Boat Repairs Illustrated cover:

how a fiberglass boat is built, identifying hull damage; materials,

tools and basic techniques; gelcoat restoration; making minor

repairs; making major repairs; hull, keel and rudder fairing;

identifying and making osmosis repairs; and finishing and painting

a repair job. There is also an appendix on building a temporary

Shrink Wrap™ shed in which to do boat repair work year-round.

With more than 200 pictures and drawings, the book shows repair

projects as done by the author and other professional and amateur

boat builders, from simply polishing the gelcoat or repairing

a ding in the paint work, to much larger projects such as making

a transom well guard to keep water from flooding over the transom.

The most ambitious project is a complete hull and keel reconstruction

on a boat that went aground and was seriously damaged.

Fiberglass

Boat Repairs Illustrated (ISBN 978-0-07-154992-9,

MHID 0-07-154992-7, ebook ISBN 978-0-07-154993-5) is published

by International Marine/McGraw-Hill. Paperback, 192 pages. US

$24.95.

******

|