| Click

here for Part 2

Part 1

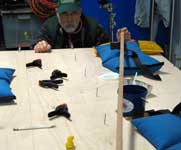

In the rush to build as many prototype hulls as possible

this year; the completed FlyCaster was quickly removed

from it's place of honor on my building platform so

the two sheets of plywood for the PUD-g could replace

it. Building new hulls has become an obsession with

me this year, and building the PUD-g seems to have

reached a peak. I hope. It may slow down a bit, as

most of the hulls queued up are too long to fit in

my current work space. I will either need to add on

to the barn, or sell out and move down to the Texas

coast where I can build and use my 18ft cat ketch,

Raid design. Or go single hulling with my 15ft asymmetrical

hulled catamaran. Where was I?

The layout of the hull panel outlines on the stacked

plywood sheets when very smoothly, with only a couple

of changes from the dimensions I had calculated off

the computer drawings. Mainly it was adjusting two

of the bow corner points so the "arc lengths"

of the two mating edges were within 1/8" of each

other. I had to use my layout batten, and measure

the distances pencil marked on some masking tape.

All my measuring tapes would cut the corners between

the brad nails and give me a false distance. I have

to get a cloth measuring tape and glue it to the batten

for use on other hulls. Once all the adjustments were

made, it was time to cut out the panels.

|

|

It had been a while since I had worked with 4x8

sheets of plywood, and they looked so small compared

to the 5x10's I had been using on the last three hulls.

Moving the clamped pairs around on the work platform

was a lot easier. I was also chuckling to myself about

how small the panel pairs were after I had cut them

out and set aside; and kept asking myself if this

was really something to spend so much time on. Since

this PUD-g is not the same hull as the PDF

model you can download in my

area of the "Plan" section.

That PUD-g, wasn't. Once I think I am done with

the basic hull design, I print, glue, cut out, and

assemble the latest model; then hang it by a thread

over my kitchen counter where I eat all my meals.

I then spend days/weeks looking at it as the model

spins in any chance breezes that pass by. Or I just

blow at it. Sooner or later, some thing about the

hull just doesn't look right, and I give it a good

"eye balling". Turning it around in my hands

and wondering what's wrong with the hull, that it

makes me second guess what I have already done. This

time the hull just didn't look big enough. I didn't

really want to make any changes, because it was too

pretty now. But I know now that a small boat, (less

than 10ft) can not be really sleek and have the volume

to carry any kind of load. A small pretty boat is

actually just a scaled down version of what it should

be to do the job.

To prove to myself that I needed to make some major

changes, I laid out the hull outline on my kitchen

floor with bits of masking tape and then sat in the

middle of it. Yep, too small. Time to add some steroids

to PUD-g's diet. Now I get to spend even more hours

at the computer, then the making of seven more models

until I was happy with the design. Which meant throwing

away several pages of completed detail drawings. :(

But as a confirmed scab scratcher, I had to do it.

Nobody is going to be more critical of my designs

than me. No one! This pudgier PUD-g is not as pretty

as the first, but can more than stand up to the demands

placed on it, and still be true to the "mission

statement" that I set out with when I first though

of designing this hull. (see the cover letter

on the PUD-g

in my plans area)

With the hull panels all cut out, it was time for

the "outside" photo. I was still wondering

what the heck I was doing when I saw the photo, but

that changed to fatherly love when I had the panels

all wired together. Like babies, kittens, and puppies,

something about miniatures brings out a protective

instinct, and an obsession to nurture. It became necessary

to force myself not to work on the boat and live "my"

life. Even as I write this I am way behind on the

plan drawings and updating the text instructions;

and the hull is 90% complete.

Hull assembly when smoothly, with no problems. I

did find a couple of flat spots along the hull seams,

but some 1/8" shims fixed those. I wasn't sure

if it was from the design or cutting out the panels.

Judging from their locations, it had to be me moving

slightly inside the line as I cut. No big deal. GelMagic

and EZ-Fillet

can cure all my mistakes.

|

|

With the PUD-g, I wanted to make a pure "deck"

boat in the ongoing wars over hard-shell or inflatable

tenders. As a ships tender, I wanted a strong workable

solution, that was 100% practical. No extra fancies

on the interior, and lots of secondary flotation in

case of a breaking wave on a beach landing. I also

needed room for people and their supplies. As a seakayaker,

I knew the benefits of watertight storage compartments,

and the extra flotation they have built in. As a whitewater

canoeist, I know of the added safety that buoyancy/displacement

air bags give in keeping you and the canoe on the

surface in big water. With that insight, I made the

interior seating on the PUD-g part of the hull, with

storage, and reserve flotation.

On the Laura Bay, I had boxed in the area around

the daggerboard case to use as extra flotation. I

now wished I had added a 4" quarter turn hatch

to each side in the plans. I will do this to my own

hull later. On the PUD-g, I have added the four inch

hatches, plus two six inch hatches on either side,

of the forward seat compartment. If you so chose,

you can add an extra bulkhead to divide it again.

Just offset one hatch forward of the other. That forward

hatch may be reduced to a four inch model to fit better.

The stern seat box is wider than the main center seat,

and is fitted with a larger eight inch hatch. All

the seat panel to hull seams are filleted with EZ-Fillet,

and a layer of 2" glass tape on the outside.

World cruisers can add a fillet to the inside seams

if you chose to do so for added strength.

Because of the heavy curvature near the bow with

this design; I have gone to the "spaced rail"

gunnel system. All the rail parts are ½"

x ¾", ripped out of Philippine Mahogany.

Once I have ripped out the rail stock, they are stacked

into two pairs. Port and starboard, with the "inner"

rail on top, to form to it's mate. The bow ends are

tied together and raised at least 18" off the

floor. The stern ends are raised about 8" off

the floor. I added some loosely tied cord at three

places along their length to keep them together, but

able to slip independently. I then placed some sandbags

on the rails, and closer to the bow end to induce

curvature. More bags are added and moved closer to

the bow end over several days as the wood takes a

set. You could also do this by making up a jig out

of an eight foot 2x4 with the two risers nailed at

each end. Then the rails could be tied to the jig,

and forced into a curve over several places. You do

not want any "point" loads. A light spraying

of water at the start can help too. The rails need

to be kept this way for a week or more to take on

a set and keep from "snapping" when you

go to install them.

|

|

Another problem I encountered was fitting the spacer

blocks to the heavy curvature. I didn't want to put

excessive pressure on the hull panel and the outer

rail by just applying massive clamping pressure to

make the spacer block conform to the hull. To get

around this, I placed "relief" cuts on the

outer side of the spacer blocks; and this let them

easily flex to fit the curve of the hull. I only had

to do this at the #2-3-4-5 station lines. The other

blocks glued up with no problems. I did change the

block spacing in the plans drawings, from what I used

on the prototype hull, after rethinking the spacing

pattern. The new scheme is a better fit.

|

|

|

|

With every new hull prototype, I spend a lot of

time thinking about seat height, and how to make sure

that measurement will remain the same from bow to

stern. Half the battle is making sure the hull is

sitting (to what I think it will be) on it's lines.

Serious head scratching, but I am usually on my (it's)

mark. With that information, I then set up a (rubegoldberg)

series of strings and scrap sticks to project that

idea to the hull. Then I go about measuring all the

heights and widths for the various parts that make

up the seat and daggerboard assemblies. After a few

cardboard cutout mockups, I can then mark and cut

out the plywood pieces. Sometimes they become backing

plates for future projects, and I go scrounging around

the shop looking for more bits leftover from previous

hulls.

|

|

|

|

The stern seat assembly went together smoothly,

with a couple of adjustments to the bottom edges of

the panels to fit the hull. The whole assembly was

jump stitched, filleted, and glass taped on the inside

before I attached it to the hull. With 6mm plywood

backing plates for the top seat panel, and for the

8" hatch area. I also added a layer of 6mm ply,

and a piece of ¾" x 1" rail material,

to the inside of the stern panel to give extra support

to the area where the rudder gudgeons

are mounted. The rail material and the set assembly

had to be relieved to fit this addition.

In order to judge how the "main" seat

assembly would go together, I had finish the daggerboard

case. The PUD-g is using a NACA 0010-8" cord

daggerboard. So I needed to figure out and design

the shape, find the overall width of the foil, and

then determine the case's open length and width to

have room for the daggerboard to "gybe"

inside it. Once that was done, I could cut and assemble

the case.

|

|

|

One of the things I remembered to do this time,

was to measure and mark a line 2" offset from

the keel line seam. On my other hulls, the filleting

and glass tape layers hid it's true location and I

had to crawl under the hulls, and drill a pilot hole

up from the bottom. With this line, I was able to

reestablish the true keel seam and mark on masking

tape that location. From my half model CE/CLR locations,

I knew where the aft side of the DB case would go.

Out comes the centerline cord and the "pencil

bobs". After making sure the hull was still level

on the work platform, I centered and aligned the DB

case, and held it in place with a weight. More sticks

to determine where the main seat would meet the bow,

and a couple bits of masking tape for that location.

Now the fun part of figuring out how the main seat

side panels would be shaped and fit to the hull. More

cardboard, mark, cut, mark, cut, mark; you get the

idea. Once I had a shape that seemed to fit, I tried

it out on the other side. Close enough for EZ-Fillet.

With them taped in place, the top seat panel was cut

out of cardboard and everything was taped together

to see if it worked. I then took some measurements

off the cardboard mockups and projected those figures

onto the plywood as a check for me and my numbers.

Then a test of faith when I cut out the plywood panels

to those measurements. There was some reshaping to

the bottom edges before finally epoxying them in place.

All hulls will have to have some reshaping due to

the variability's of construction.

|

|

|

With all the parts cut and shaped, it was time to

start making things permanent. The daggerboard opening

in the hull was located and marked with some pilot

holes. I do the cutout when the hull is upside-down

getting it's bottom glassed. The DB case is located,

jump stitched, then EZ-Filleted and glass taped in

place. The main seat top and side panels have their

backing plates attached with epoxy or GelMagic;

and the hatch openings located and made. Everything

is then coated on all the inside panel faces and edges

with two coats of epoxy. The main seat side panels

are then attached to the DB case with some stainless

pilot screws to maintain alignment, and a thick layer

of GelMagic on all the mating surfaces. The top front

width of the side panels is checked and held in place

with a bit of scrap and clamps or screws. The side

panel to hull seams are jump stitched and everything

is left to cure.

The mast step/partner assembly on the PUD-g is a

bit different than on my other boats. I haven't finished

with it yet, so this is a good place to stop for the

time being. To see a lot more photos of the construction

process to date for the PUD-g; go to the following

link. I will be adding photos until/after the plans

are ready for sale. www.flickr.com/photos/pud_g

|

Click the image

at left to download a printable paper hull model

of the PUD-g |

Thanks again for reading my stories. I look forward

to your comments.

Warren Messer

Red Barn Boats

Click

here to proceed to Part 2

Plans

and study plans for PUD-g available here

Other Articles by Warren Messer

|